Slip Ring Robotic Applications | Reliable Power for Robots

Slip Ring Robotic Applications: Reliable Rotation for Modern Robots

Slip Ring Robotic Applications: Reliable Rotation for Modern Robots

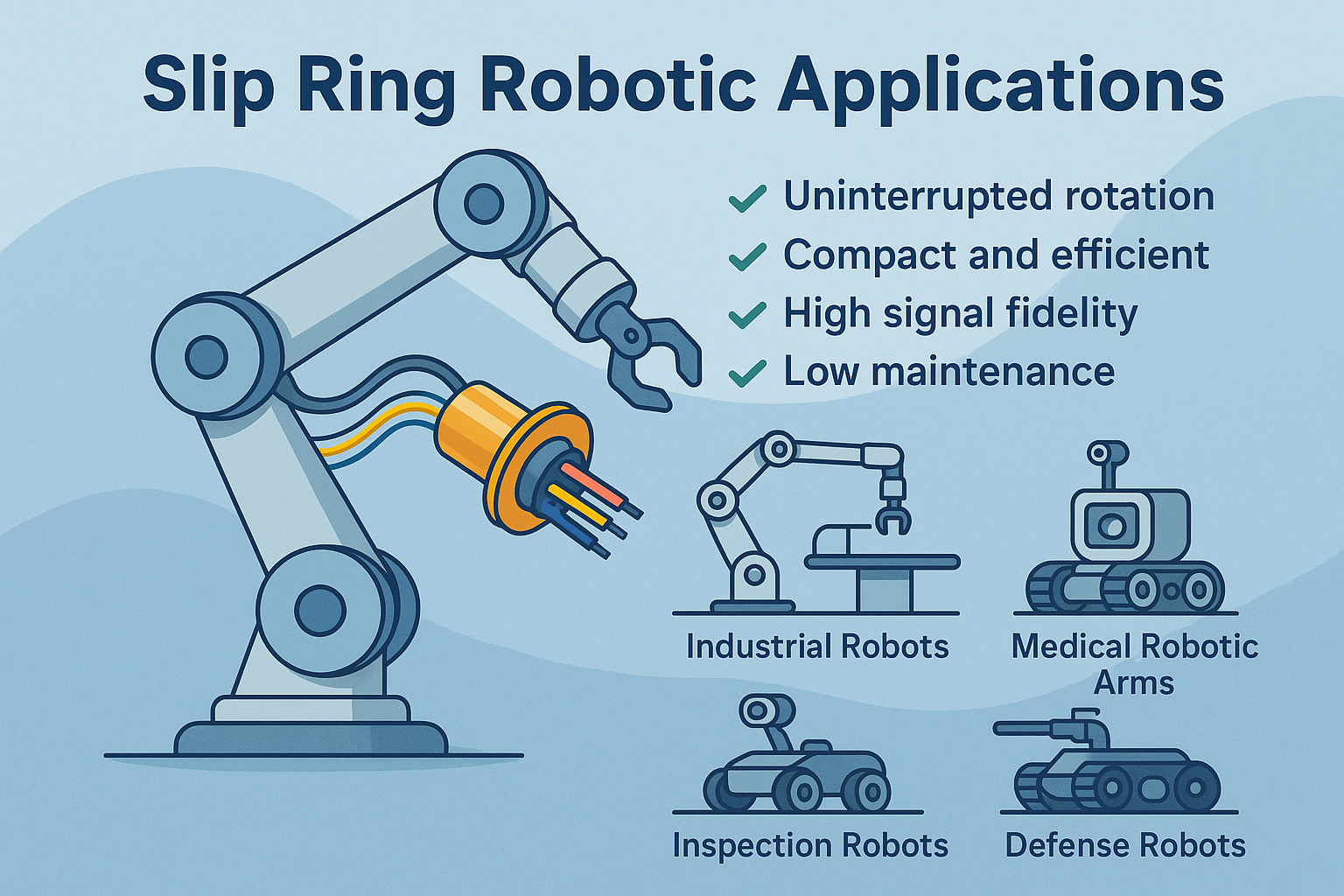

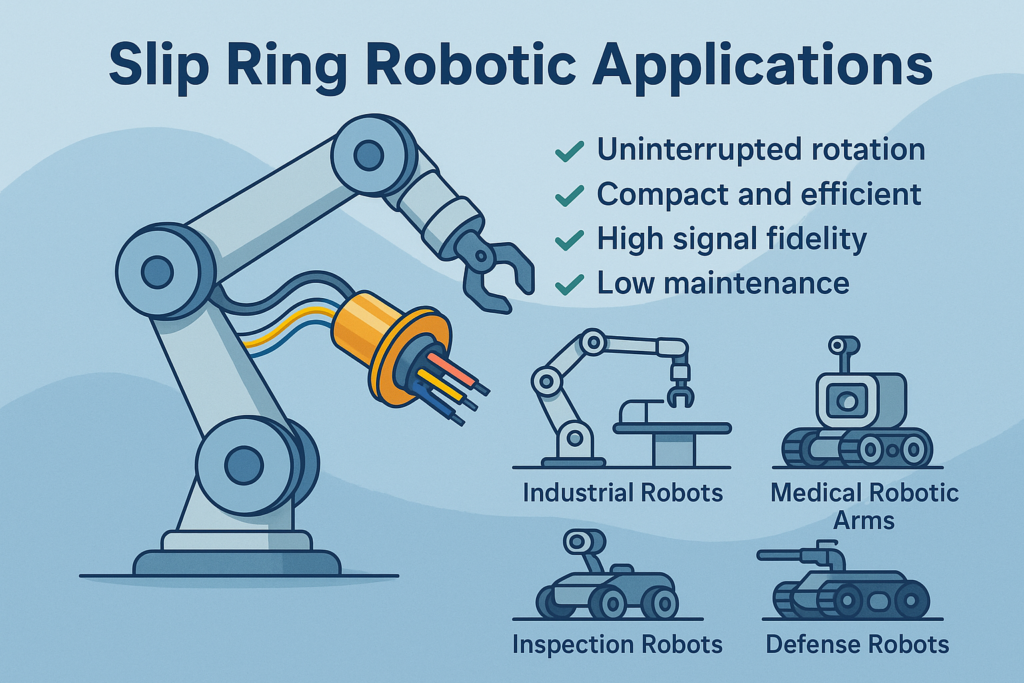

Slip ring robotic applications play a key role in powering today’s advanced robotics. These devices enable the continuous transmission of electrical signals and power through rotating joints. Thanks to this technology, robots can move freely while maintaining data and energy integrity.

What Are Slip Rings and Why Are They Essential?

What Are Slip Rings and Why Are They Essential?

A slip ring is a rotating connector that allows electricity and signals to pass between stationary and moving components. In robotics, it prevents cable twisting and ensures smooth operation.

Key Advantages for Robotics

Key Advantages for Robotics

These components offer several important benefits:

-

Continuous 360° rotation

-

Space-saving compact structure

-

Stable high-speed data transmission

-

Reduced maintenance and downtime

Applications Across Robotic Fields

Applications Across Robotic Fields

Slip rings are used in a wide variety of robotic systems. For instance:

-

Industrial robots in production lines

-

Medical robotic arms for surgical tasks

-

Inspection robots navigating enclosed spaces

-

Defense robots with rotating sensor systems

Choosing the Right Component

Choosing the Right Component

Selecting the ideal slip ring depends on several factors. These include signal types (digital or analog), voltage and current levels, space limitations, and environmental conditions. In many cases, custom-designed slip rings are preferred for high-performance robots.

Conclusion

Conclusion

To sum up, integrating slip ring technology into robotics increases performance and flexibility. These components help systems function smoothly and safely without signal loss. Whether in manufacturing or medical applications, reliable rotation starts with the right slip ring.