Slip Ring Filling Machines | Precision Power & Control

Slip Ring Applications in Filling Machines: Reliable Rotation for Precision Packaging

Slip Ring Applications in Filling Machines: Reliable Rotation for Precision Packaging

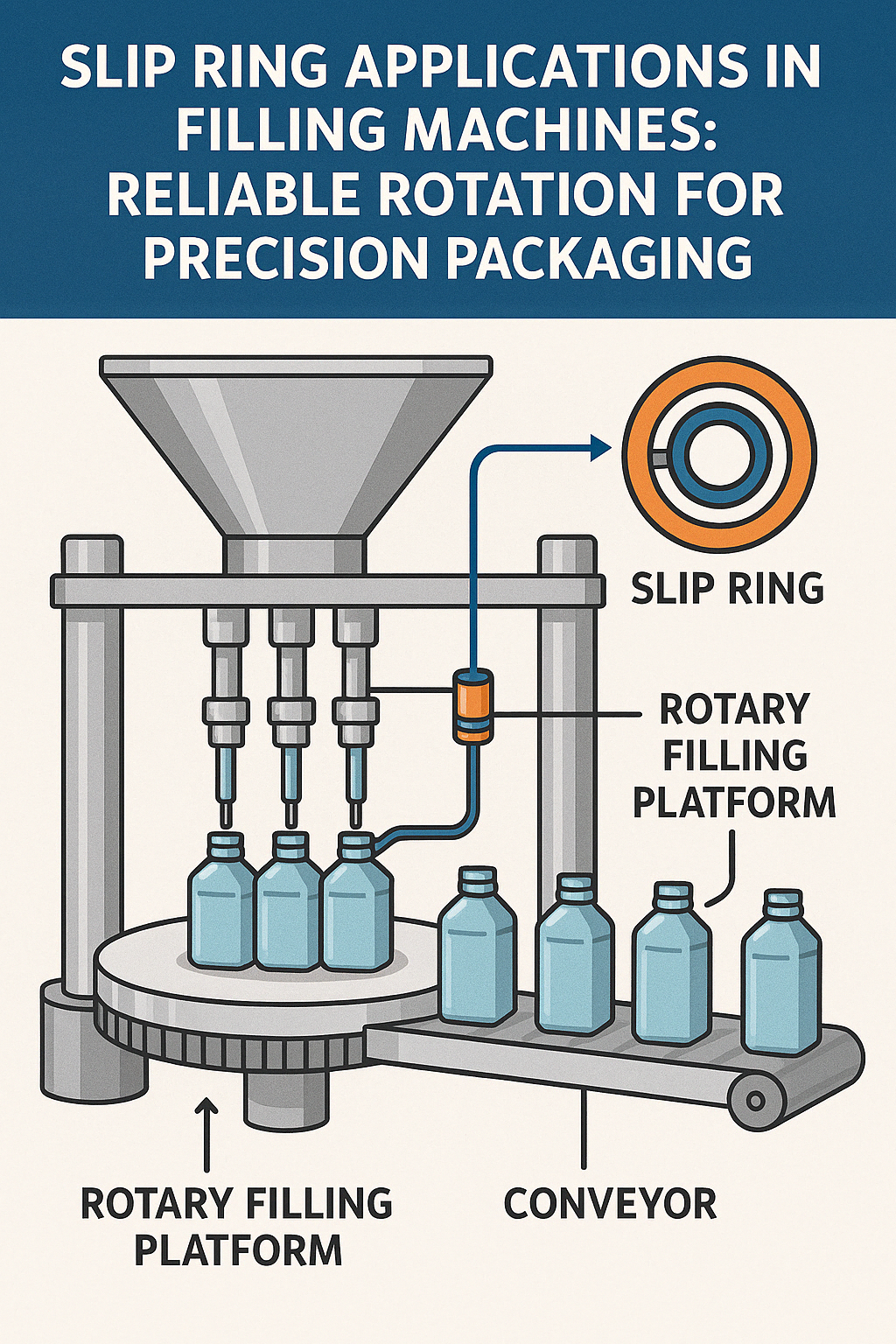

In the fast-paced world of industrial packaging, filling machines are essential for high-speed, accurate dispensing of liquids, powders, and gels. Many of these systems operate with rotating components—such as filling heads, carousels, and cappers—that require uninterrupted power, control signals, and sometimes data transmission. This is where slip rings become a crucial element.

Why Filling Machines Need Slip Rings

Why Filling Machines Need Slip Rings

Filling machines often feature rotary motions that would twist or damage traditional cabling. Slip rings solve this problem by enabling:

-

Power delivery to rotary actuators or motors

-

Control signal transmission for valve timing and filling accuracy

-

Sensor feedback (e.g., level sensors, flow meters) from rotating parts

-

Optional pneumatic or fluid rotary joints for hybrid designs

This allows for 360° continuous rotation without interruption or cable wear, increasing uptime and reducing maintenance costs.

Common Industries Using Slip Rings in Filling Machines

Common Industries Using Slip Rings in Filling Machines

-

Food & Beverage

→ Bottling lines for water, soda, milk, oil, etc. -

Pharmaceutical

→ Sterile filling systems for syringes, vials, and IV bags. -

Cosmetics & Personal Care

→ Perfume, cream, and gel dispensing machines. -

Chemical & Industrial Fluids

→ Filling lines for detergents, lubricants, paints, and solvents.

What Makes a Slip Ring Suitable for Filling Machines?

What Makes a Slip Ring Suitable for Filling Machines?

-

Compact and hygienic design

-

IP-rated enclosures (IP65 or higher) for washdown and contamination resistance

-

Low torque and low electrical noise for accuracy

-

Stainless steel or food-grade housing options

-

Support for pneumatic/hydraulic lines (if combined with rotary unions)

Customization and Integration

Customization and Integration

Slip-ring.com offers tailored solutions for filling machine manufacturers and integrators. Features include:

-

Through-bore or capsule designs

-

Integration with signal types (Ethernet, RS485, CANbus)

-

Modular combination with rotary unions

-

MIL-spec or industry-standard connectors

Conclusion

Conclusion

In modern filling machines, precision and uptime are key. Slip rings play a silent but vital role by enabling uninterrupted power and signal transfer across rotating components. Whether in a dairy bottling plant or a pharmaceutical cleanroom, the right slip ring ensures smooth, continuous operation with maximum efficiency.